Case Study: Beta Technologies Validates ALIA eVTOL Electrical System Using B&K Precision's DAS1800 and DAS240

Overview

Beta Technologies, a pioneer in electric vertical takeoff and landing (eVTOL) aircraft, developed the ALIA series to advance sustainable aviation. To ensure reliability and safety, Beta needed to validate the electrical system which provides power to the electric motors. By leveraging B&K Precision's DAS1800 and DAS240 data acquisition recorders, Beta effectively addressed a variety of challenges associated with the development of advanced electric propulsion.

Challenges

Challenges

Beta Technologies needed to validate the electrical system providing power from batteries to the electric motors used for propulsion. Key challenges included:

1. Power Delivery Testing: Ensuring safe and reliable power flow from the battery system to propulsion motors by simultaneously measuring high voltages and currents.

2. Transient Event Monitoring: Capturing high-speed transient voltages and currents during open fuse simulations.

3. Thermal Monitoring: Measuring temperatures to ensure critical component longevity and system reliability.

4. Remote Configuration and Control: Including the ability to load configuration files for specific tests, start and stop acquisitions, and visualize data remotely.

5. Data Synchronization: Synchronizing all measurements across voltage, current, and temperature channels.

6. Scalability: Allowing the system to scale for testing from 1 to 5 electric motors for propulsion

Challenges

Beta Technologies needed to validate the electrical system providing power from batteries to the electric motors used for propulsion. Key challenges included:

1. Power Delivery Testing: Ensuring safe and reliable power flow from the battery system to propulsion motors by simultaneously measuring high voltages and currents.

2. Transient Event Monitoring: Capturing high-speed transient voltages and currents during open fuse simulations.

3. Thermal Monitoring: Measuring temperatures to ensure critical component longevity and system reliability.

4. Remote Configuration and Control: Including the ability to load configuration files for specific tests, start and stop acquisitions, and visualize data remotely.

5. Data Synchronization: Synchronizing all measurements across voltage, current, and temperature channels.

6. Scalability: Allowing the system to scale for testing from 1 to 5 electric motors for propulsion.

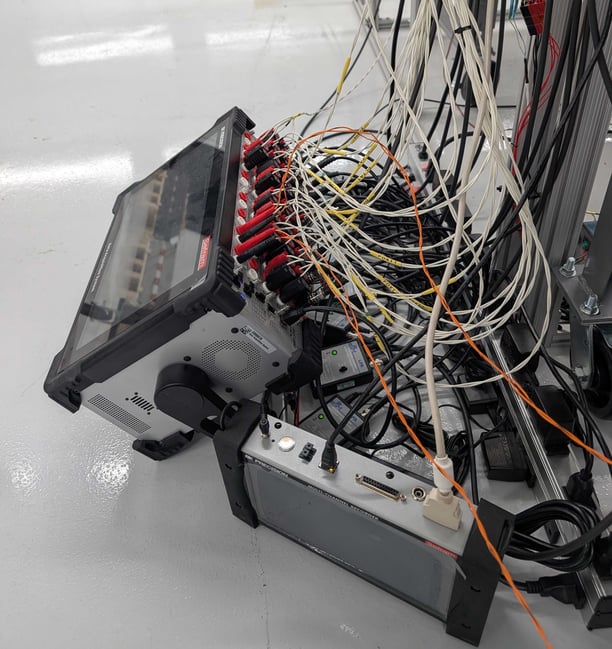

(The DAS1800 and DAS240 shown in the image above are started remotely and synchronized via Ethernet in Beta Technologies' test facility.)

Solution

To address these challenges, Beta Technologies selected B&K Precision's DAS1800 and DAS240 data acquisition recorders.

- DAS1800: Used to measure battery and circuit voltages, and currents using current transducers (CTs). The DAS1800 was equipped with HVM-4 High Voltage input modules for measuring voltages up to 1,000 Vrms, and UNI-4 Universal Input modules for measuring current with CTs. Each DAS1800 can simultaneously acquire and log up to 40 channels at sampling rates up to 1 MSa/s.

- DAS240: Used to monitor temperatures across critical components to ensure operational reliability and lifespan. The DAS240 provides 20 universal inputs, which can be expanded to 200 using additional terminal blocks. The universal inputs provide built-in signal conditioning, and allowed for measuring temperature with thermocouples at rates up to 1,000 Sa/s.

These devices provided synchronized measurements of voltage, current, and temperature, enabling comprehensive analysis of the electrical system. Built-in Ethernet ports and support for remote control via SCPI commands allowed Beta engineers to integrate the data acquisition recorders into a larger test system and execute tests remotely.

DAS1800 High Speed Modular Data Acquisition Recorder

DAS240 Multi-Channel Data Recorder

Results

The DAS1800 and DAS240 delivered significant benefits to Beta Technologies:

- Enhanced Safety Testing: Simulated fuse operation, and validated reliable system behavior during overcurrent events.

- Transient Data Insights: Captured transient voltages and currents to ensure electrical system performance during fault conditions.

- Thermal Assurance: Monitored component temperatures to maintain system reliability and extend operational lifespans.

- Operational Efficiency: Enabled flexible and efficient remote testing and data handling.

- Scalable Testing: Supported synchronized measurements for propulsion systems with up to five motors.

Beta Technologies Alia Aircraft:

Conclusion

Beta Technologies successfully validated the ALIA eVTOL's electrical system by leveraging B&K Precision's DAS1800 and DAS240 data acquisition recorders. These tools enabled accurate and efficient testing, ensuring the ALIA series met the highest safety and performance standards, advancing sustainable aviation.

Learn more

To learn more about the products featured in this case study, visit the product pages below.